the eye of technology

We deliver computer vision solutions purpose-built for heavy industry and energy applications. Our systems detect equipment damage with high accuracy, enable predictive maintenance to prevent costly failures, and optimize production processes for maximum efficiency — helping industrial leaders achieve safer, more reliable operations

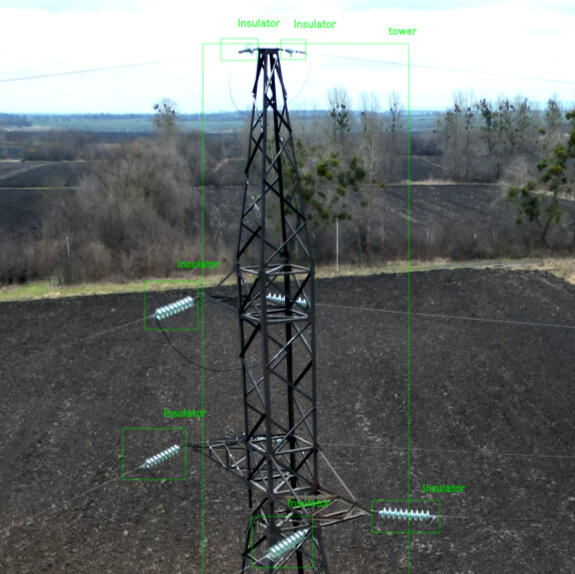

Case: Damage Detection

Our damage detection solution leverage advanced computer vision to analyze imagery captured by a drone. The system can pinpoint issues such as insulator cracks, corrosion, conductor damage, vegetation encroachment, and structural deformations — all with high accuracy and consistency. Automated detection reduces reliance on human inspection, cuts the risk of overlooked defects, and allows maintenance teams to focus resources where they are needed most, eventually decreasing downtime and number of outages in the energy grid

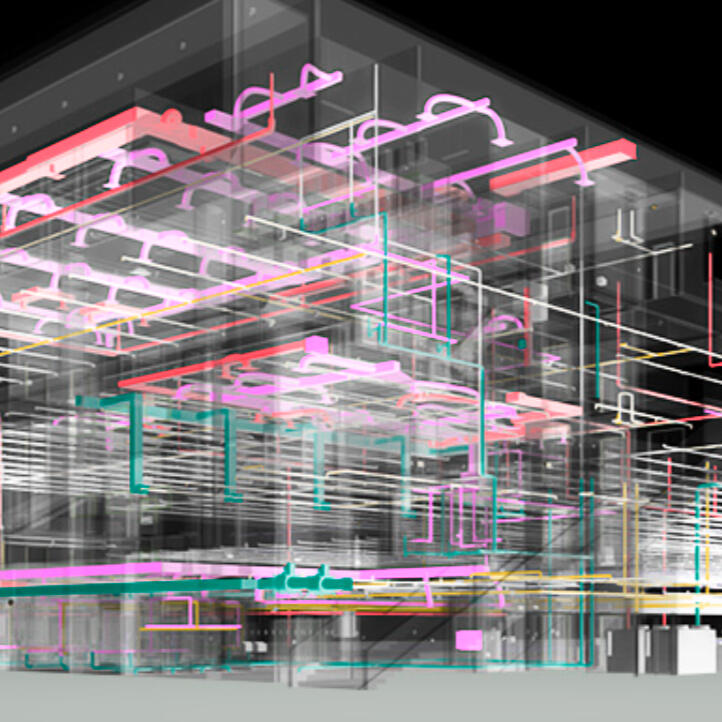

from satellites to sensors

We work with a wide range of data sources — from thermal cameras and drone imagery to LiDAR scans and field sensors — and prepare datasets through labeling, cleaning, and augmentation. By combining these foundations with advanced computer vision techniques, we build systems that are not only accurate but also robust and field-ready

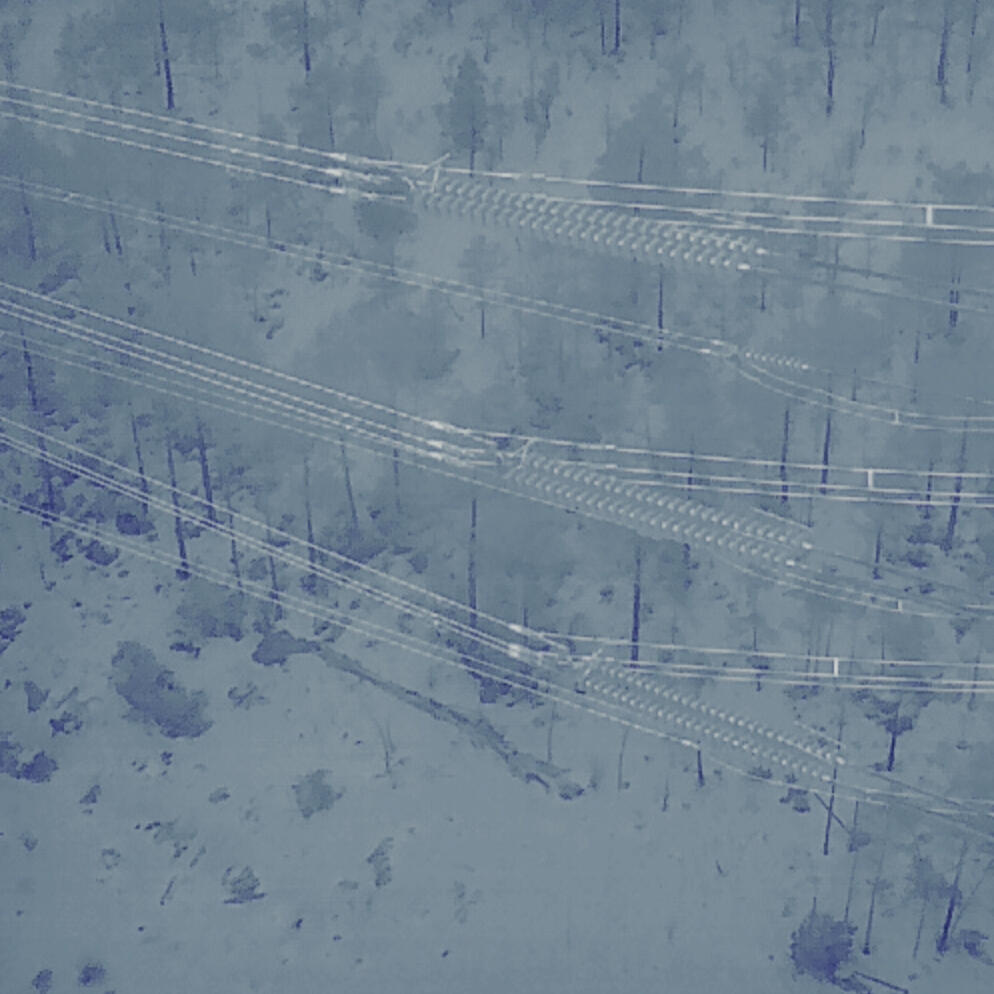

Case: Equipment Monitoring

Our computer vision solution automates the analysis of thermal imagery, enabling fast and reliable detection of anomalies across power line equipment. Advanced algorithms identify abnormal heat distributions, classify defect types, and prioritize issues by severity, reducing the need for manual review and ensuring that no critical sign is overlooked. This approach supports utilities in optimizing inspection workflows while improving diagnostic accuracy. Early detection of overheating components extends equipment lifespan and prevents unplanned outages

deep sector insight

Our experience across heavy industry, energy, oil & gas, and waste management enables us to design solutions tailored to the unique challenges of each domain. From monitoring critical equipment and detecting failures to improving safety and streamlining operations, we align technology with the realities of industrial environments

Case: Sustainability Analysis

Our solution applies advanced vision models to track equipment performance, detect leaks in pipelines, identify energy losses, and monitor compliance with standards. By automating these processes, facilities can reduce waste, lower greenhouse gas emissions, and prevent hazardous incidents that harm both people and the environment. Continuous monitoring generates actionable data that helps companies fine-tune operations, extend equipment lifespans, and align with sustainability goals and regulatory requirements

turning data into actions

We apply a broad range of data analysis and machine learning techniques, including time-series forecasting, anomaly detection, clustering, and optimization. By integrating these approaches, we deliver actionable intelligence that supports faster, smarter decision-making, reduces uncertainty, and drives operational excellence

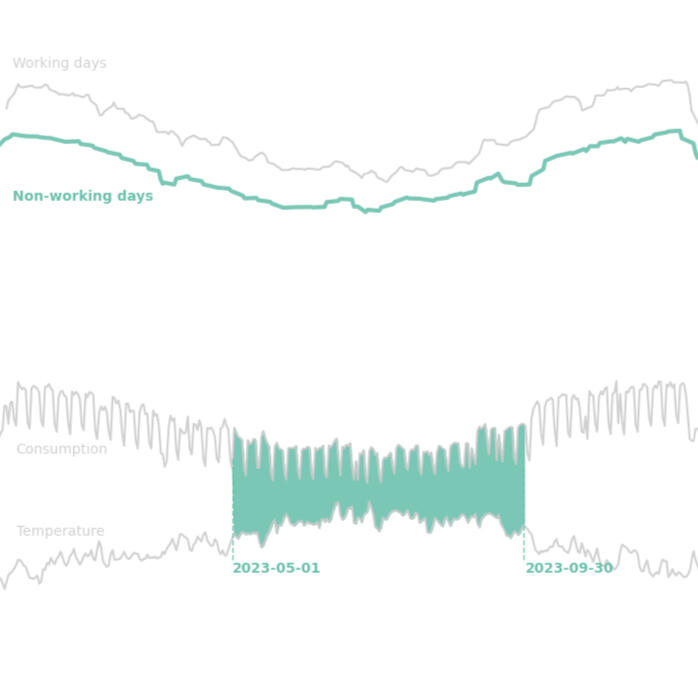

Case: Domain-Specific Research

Our approach combines advanced machine learning with domain-specific modeling to predict grid consumption across diverse scenarios. Time-series analysis of historical usage is enhanced with weather forecasts to capture temperature-driven demand shifts, while geospatial data — including the location and capacity of substations, lines, and feeders — helps reflect the physical constraints of the network. The result is improved planning and resource allocation: from balancing load and scheduling maintenance to integrating renewables and expanding capacity in high-growth areas